Welcome to the Lofting Experience

English

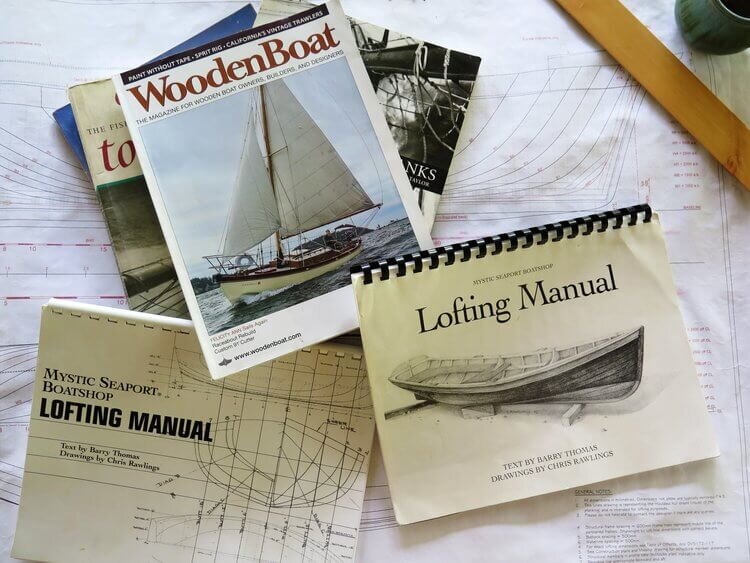

After almost completing the shipyard infrastructure, the first curves and lines started to shape Ceiba. Shani took part of the lofting workshop led by master shipwright Bert van Baar from the Netherlands and gives insight into the art of drawing a boat.

After eight months at the jungle shipyard the lofting floor is now really taking shape and by the time you are reading this, our first master shipwright - Bert van Baar - will be here with us, all the way from the Netherlands, to begin the first phase of the process. You may be wondering what have we been doing these last 8 months if lofting is only beginning now? Aren’t we supposed to be building a ship? If you were to come for a visit, some might have said no, we are in fact, here to become professional hole-diggers, peelers and weed-wackers. This is partly true, as a huge portion of the work as been taken up by such labour-intensive and menial tasks. Why? To create the ship’s environment, i.e. the shipyard - an essentially important part of the story, without which Ceiba would be unable to come into being.

El Astillero Ceiba del Mar has been created completely from the ground up, by the team at the shipyard, which has included building structures such as the metal workshop, giant woodshed, and enormous ship’s hanger. On the right day, I might argue that hole-digging can actually be quite therapeutic, however, either way, it has all been worth it and a lot of preparatory learning has been taking place in readiness for the construction of the 148ft schooner.

Simon stacking the plywood boards in place a few weeks ago, ready to be painted in white in preparation for laying the lofting floor.

“El Astillero Ceiba del Mar’ has been created completely from the ground up, by the team at the shipyard, which has included building structures such as the metal workshop, giant woodshed, and enormous ship’s hanger.”

A view across the level white expanse of the working lofting floor with the keel blocks stretching out in the background behind.

Now we are at that stage that everyone has been waiting for. With two-thirds of the keel laid ready in place next to the keel blocks, the lofting floor itself being laid as I write, and with our first shipwright arriving this weekend, we can finally say Ceiba’s physical form has begun to take shape.

“We are at that stage that everyone has been waiting for. Keel timbers are in place, the lofting floor being laid as I write, and our first shipwright arriving this weekend: Ceiba’s physical form has begun to take shape.”

Next to the intensive milling of the enormous tamarindo del monte hardwoods and under the big guanacaste blanco tree, the large white expanse of the lofting floor stretches out to meet the edge of the Pacific Ocean alongside which the shipyard lies.

When completed, this floor is going to feel enormous and will truly prepare us for the scale of the ship once this blank white canvas brings her to life through a myriad of calculated and intricate lines.

Shani & Charlie (a.k.a. Prince Charles) getting ready to ‘rip’ some Tamarindo del Monte with the Alaskan Mill. Just beyond, out of sight, lies the lofting floor and the keel foundational posts.

Lofting, lofting, lofting…!

So what exactly is lofting?

Lofting is a technical drawing or drafting technique whereby curved lines are created to form the shape of the streamlined object in full-sized patterns. The process has been used in the construction of seafaring vessels as well as aircraft, but is particularly useful in boatbuilding, where it is necessary to draw and cut lines for keels and hulls which are curved often in three dimensions. This way of ship building was the norm before the introduction of computer-aided design, however, the technique can be as technological as plotting the lines with the use of computers or mathematical tables, or as simple as bending a flexible object, such as a thin piece of wood, over three non-linear points and drawing the resulting curved line.

Lofting is a traditional craft that has become a science with the help of technology, and designers have come up with various ways to construct long curves on flat surfaces. The name of this process originates from the fact that it was usually carried out in large, lightly-constructed lofts above a factory floor, which was often a level wooden surface made up of plywood boards, exactly like the one here at our shipyard in Costa Rica.

“Bert has been a boatbuilder for 16 years and he has built 70 boats to date - an amazing accomplishment and someone who we are very grateful to have within our midst to share and learn from.”

The drawings of Ceiba, laid out in intricate lines.

As mentioned before, Bert van Baar will be arriving, with his wife, Joke Valentien, as our first shipwright and will be here for around one month to begin the lofting with us. Bert comes from the Dutch-based Hout en Meubileringscollege (HMC), from where we have already taken on two interns, Iris Overdevest and Melle van Haalen, who spent the first quarter of 2018 helping to bring the shipyard to life, by sharing their hard work and skills learnt through the creation of a beautiful wooden canoe and an amazing reconstruction of the ‘Super Koala’ aeroplane, respectively, both under the tuition of Bert at the college in Amsterdam. Before the end of the year, another of their students will be coming to the shipyard on internship to continue the relationship with the well-known institution. Bert has been a boatbuilder for 16 years of his life and he has also already built 70 boats to date - an amazing accomplishment and someone who we are very grateful to have within our midst to share and learn from.

In celebration of Bert’s visit, we have decided to set things off to a flying start with a two-day intensive workshop on lofting. Next week the two-day lesson will be an all inclusive, step-by-step curriculum which will cover all we need to know to loft a 5m (15ft) wooden boat. The workshop is free of charge and open to anyone in the community and further afield, providing a unique and much sought-after opportunity for those interested in this area of knowledge. This is a technical event where anyone can learn the first phase of building a boat: drawing out the curves into scaled patterns. Setting the standard for lofting the ship, this will serve as a learning experience and essentially, as a test run in preparation for the giant that is Ceiba.

“This project is incredible in its tenacity of belief in its own success; without the continuity of effort being put into this notion to bring it to reality, this project would be no more than just that, an idea. ”

If we have the team, the manual, the first shipwright, then what are you waiting for? This project is incredible in its tenacity of belief in its own success; without the continuity of effort being put into this notion to bring it to reality, this project would be no more than just that, an idea. All those who have come together, investors, volunteers and professionals alike have worked tirelessly together to bring everything to this stage. And now we are here, on the eve of drawing the first line, so really, we welcome you to join Project Ceiba!

Joke & Bert outside of the front of their sweetest new little house, barely 100m from the shipyard in Punta Morales.

If you are interested in investing to help us complete the lofting floor, please get in touch TODAY to be in for a chance to receive special investor incentives and benefits - just click the button below.

Our project is funded entirely by people like you becoming shareholders through investing.

Support the change you want to see in the world by getting involved with us here @SAILCARGO INC.